- Model No.: KRA0049

- Die Casting Method: Precision Die Casting

- Machining: Machining Center

- Surface Preparation: Polishing

- Tolerance Grade: 6

- Certification: ISO 9001:2008

- Trademark: Not Available

- Origin: Mainland China

- Die Casting Machine Type: Hot Chamber Die Casting Machine

- Application: Automotive Parts

- Material: Aluminum

- Pressure Chamber Structure: Horizontal

- Casting Surface Quality Level: 2

- Size: Customizable

- Specification: ISO 9001:2008

- HS Code: 76109000

Product Description

High Quality Aluminum Pressure Die Casting Molds and Components

| Series of molds | Squeeze casting mold |

| Die casting mold | |

| Stamping mold | |

| Silicon rubber mold | |

| Blowing mold | |

| Plastic injection mold | |

| Series of products | Auto parts |

| Household appliances | |

| Bathroom fixtures | |

| Medical devices | |

| Construction equipment | |

| Electrical appliances | |

| Others | |

| Series of services | Product design |

| Rapid prototyping | |

| Mold manufacturing | |

| Product manufacturing | |

| Finished product assembly | |

| Characteristics and advantages of squeeze casting | High density |

| Smooth surface | |

| Fine grain structure | |

| Excellent performance | |

| Precise dimensions |

1. OEM and ODM 100%

2. High quality

3. Best service and best products

4. Advanced technology and equipment.

As a supplier, we are confident in our company because we have the following advantages:

1. 15 years in die casting mold making

2. Precision molds with 0.005mm tolerance

3. Mold life from 30k to 1200k, hardness 32-56HRC

4. OEM/ODM for die casting molds and parts

5. Advanced R&D technology

6. Rapid prototyping available

Casting Equipment

1. High pressure die casting machines: 125T/180T/250T/280T/500T/800T/1250T

2. Gravity casting machines: 5 production lines

3. Low pressure die casting machines: 1 production line

4. Sand casting machines: 6 production lines

5. Degassing equipment for material refinement

6. Machining: 5 sets of CNC machines, 3 milling machines, 3 turning machines, 10 drilling and tapping machines

Main Products

Contact Information:

Contact Person: Amy Chen

Tel/Fax: +86-021-37631922

Mobile: +86-136 0748 6253

Address: No. 528, Xinyu Road, Songjiang District, Shanghai, China

--- Let me know if you'd like this formatted for a website or optimized for SEO!

TORICH is focusing on Honed Tube manufacturing and exporting,

ID Honed Tube

seamless honed tube where the surface is honed or skiving roller burnish, and the tubes are stress relieved and annealed if it is necessary.

Â

The Steel Tubes are produced according to technical standard ofÂ

EN10305-1 Cold Drawn Seamless Steeel Tubes

EN10305-2 Cold Drawn Welded Precision Steel TubesÂ

Seamless and Welded DOM tubing are produced by material of E155,E195,E235,E275,E355 +C +LC +SR +A +N

Â

DOM is a process that is applied to tubing after it is initially constructed.

It is referred to as Seamless ,It can be said that do seamless process method on ERW tubes,

So the tubes will have a high strength ,high quality.

DOM tubing is commonly use in auto parts and machinery parts, also for heavy engineering industry.Â

Â

Big Diameter Honed Tube, Skiving Roller Burnished Tube, max ID 650mm, max length 12000mm

Â

Â

Production facility for ID Honed and Skiving Roller Burnished Steel Tube

Â

Â

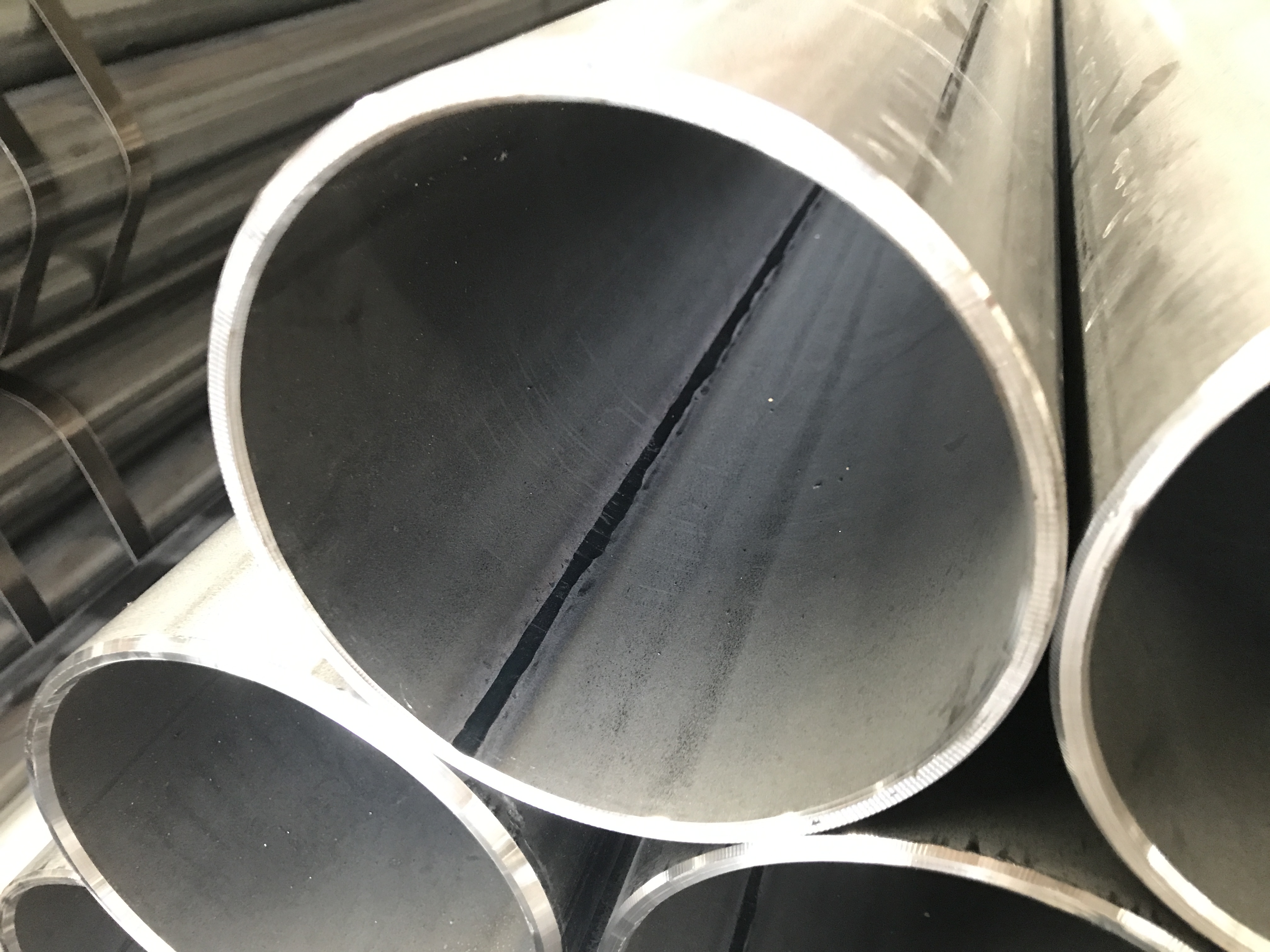

ERW mother tube for Honed Tube

Â

Â

Seamless Steel Tubes in Cold Drawn Production for ID Skiving Roller Burnish Production:

Â

Stainless Steel Pipe ready for ID Honing

Â

Â

Honed Finish ID for Stainless Steel Pipe:

Â

Honed Tube,Honed Pipe,Honed Stainless Steel Tubing,Seamless Steel Honed Tube

TORICH INTERNATIONAL LIMITED , https://www.steeltubepipechina.com