| Product name: | Plastic Mold Core Cavity Insert |

| Product Function: | Used to shape plastic products in injection molding machines. |

| Material: | Plastic mold steel (S136, SKD61, SKH-51, HPM38, STAVAX, 1.2343, 1.2344, 1.2767, 8407, etc.) |

| Profile Tolerance: | Can be ±0.005mm |

| Surface Treatment: | Mirror Polished, Technical Polished, Mold Tech Texture, Nitriding, Plating, VDI Texture, etc. |

| Transport Method: | Below 500 lb by air, above 500 lb by sea. |

| Delivery Time: | 10-15 days after payment. |

| Production Type: | OEM & ODM Manufacturer (Custom Machining Part Services) |

| Customized Type: | Non-standard product based on client's 2D/3D drawings; standard product conforms to DIN, HASCO, MISUMI, and international standards. |

| Equipment: | CNC lathe, Wire cutting, EDM, Stamping punching machines, CNC machining, Automatic lathe, Grinder, Drilling Milling Machines, Profile projector, Height gauge, 3D measuring instrument, Tool makers microscope, Thickness meters, Laser mark machine, etc. |

| Quality Control: | 100% inspection before shipment. |

| Trade Term: | EX WORK, FOB, CIF, CFR, etc. |

| Payment Method: | T/T, L/C, D/A, D/P, Western Union, Credit Card, etc. |

| MOQ: | 2 pcs, depending on order details. Small batch orders are accepted. |

| Sample: | Trial samples can be provided. |

Products Show:

Company Information:

XingRui Precision Mould Co., Ltd is a professional manufacturer specializing in precision molds, mold parts, CNC machined components, and hardware parts. We provide OEM and customized services tailored to your specific needs. Our company was founded on the principles of integrity and ethical business practices, aiming to build long-term, mutually beneficial relationships with our customers and suppliers who share our vision for sustainable development. With a lean manufacturing approach, strict quality control, and efficient inventory management, we deliver competitive pricing and high-quality products. Our team is dedicated to providing personalized service, and we welcome you to join us in this industry.

Shipping & Packaging:

Shipping: If the quantity is small or you need it urgently, we recommend shipping via express services like DHL, FEDEX, UPS, TNT, EMS, etc. For larger quantities, we suggest sea or air freight. The port of shipment is Shenzhen.

Packaging: Full consideration given to actual conditions: foam/wooden box, anti-rust paper, anti-rust oil + plastic bag + carton, or as per client requirements.

Why Choose Us:

1.Quality: High-grade original materials used.

2. Integrated production line machines.

3. Mature processing techniques.

4. Skilled and experienced workforce.

5. Strict quality control procedures.

6. Competitive pricing with reasonable margins.

7. Fast response time—any inquiry will be replied within 24 hours.

8. Quick delivery and prompt replies.

9. One-year warranty with no conditions.

Contact Us:

ADD: NO.14, SHUNXING ROAD, DAJINGTOU 2ND INDUSTRIAL ZONE, DALANG TOWN, DONGGUAN CITY, GUANGDONG, CHINA.

TEL: +0086 769 82226228

Mobile: +0086 13669850956

TORICH is focusing on Honed Tube manufacturing and exporting,

ID Honed Tube

seamless honed tube where the surface is honed or skiving roller burnish, and the tubes are stress relieved and annealed if it is necessary.

Â

The Steel Tubes are produced according to technical standard ofÂ

EN10305-1 Cold Drawn Seamless Steeel Tubes

EN10305-2 Cold Drawn Welded Precision Steel TubesÂ

Seamless and Welded DOM tubing are produced by material of E155,E195,E235,E275,E355 +C +LC +SR +A +N

Â

DOM is a process that is applied to tubing after it is initially constructed.

It is referred to as Seamless ,It can be said that do seamless process method on ERW tubes,

So the tubes will have a high strength ,high quality.

DOM tubing is commonly use in auto parts and machinery parts, also for heavy engineering industry.Â

Â

Big Diameter Honed Tube, Skiving Roller Burnished Tube, max ID 650mm, max length 12000mm

Â

Â

Production facility for ID Honed and Skiving Roller Burnished Steel Tube

Â

Â

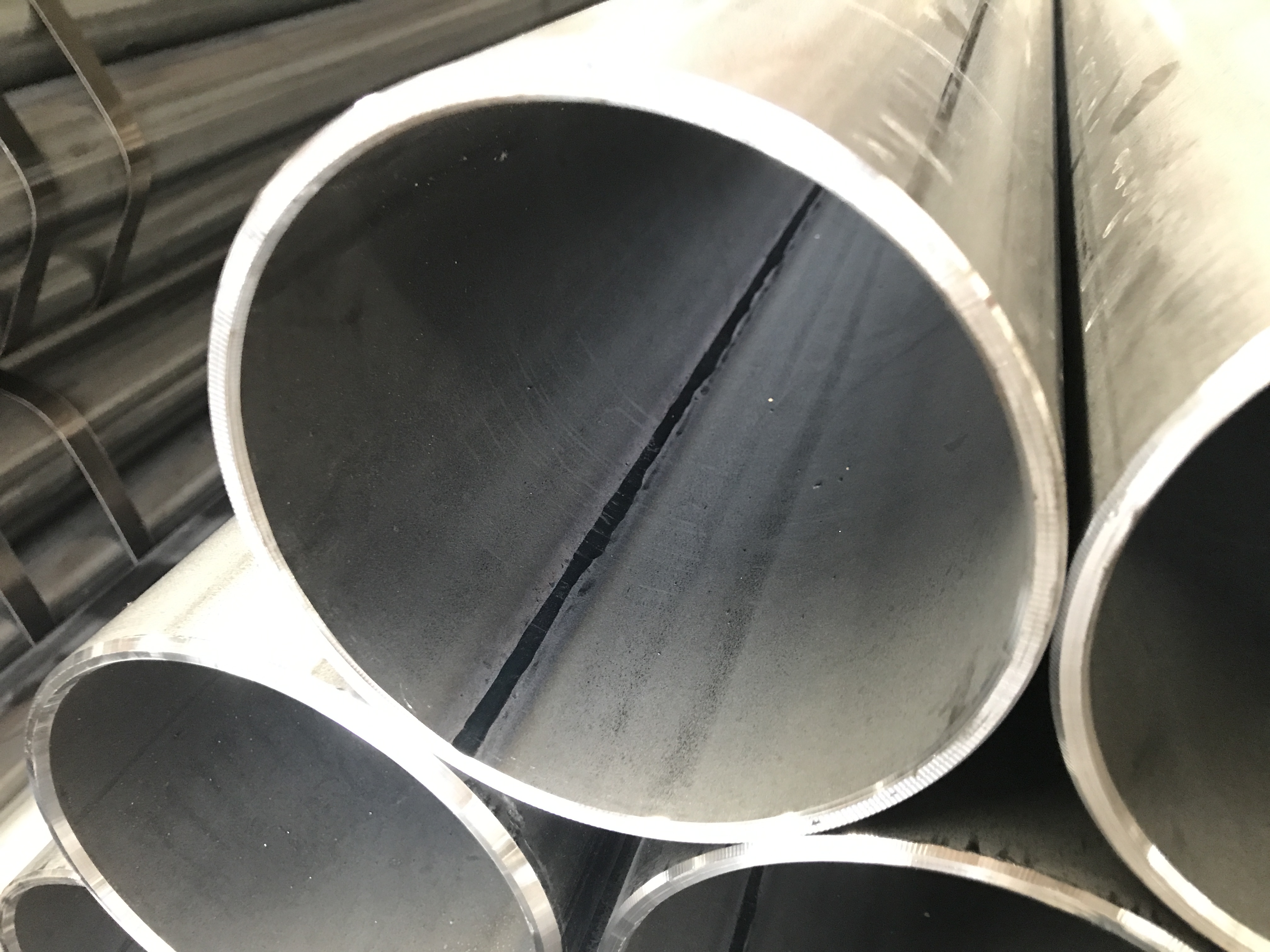

ERW mother tube for Honed Tube

Â

Â

Seamless Steel Tubes in Cold Drawn Production for ID Skiving Roller Burnish Production:

Â

Stainless Steel Pipe ready for ID Honing

Â

Â

Honed Finish ID for Stainless Steel Pipe:

Â

Honed Tube,Honed Pipe,Honed Stainless Steel Tubing,Seamless Steel Honed Tube

TORICH INTERNATIONAL LIMITED , https://www.steeltubepipechina.com