“Get Your Fix†Part 2 of 10: YORK® YLAA

Continuing our countdown of the top ten commercial OEM condenser coils that have faced issues over the past decade, we now take a closer look at the York® YLAA series — a unit that has become infamous for its durability and performance problems.

As we continue with our coil issue countdown, we’re diving into the YORK® YLAA chiller — a model that’s had its fair share of operational headaches. The YLAA series is particularly known for its problematic microchannel condenser coils, which often lead to leaks and maintenance challenges. In fact, we receive multiple calls each week from contractors and end users who are dealing with these issues.

Customers are generally unhappy with the durability of this OEM model, which has taken a toll on York’s reputation. While York did offer both microchannel and copper tube options, the latter is rarely seen in the field. Most YLAA units come with microchannel coils, which are more prone to failure over time.

The usual suspects

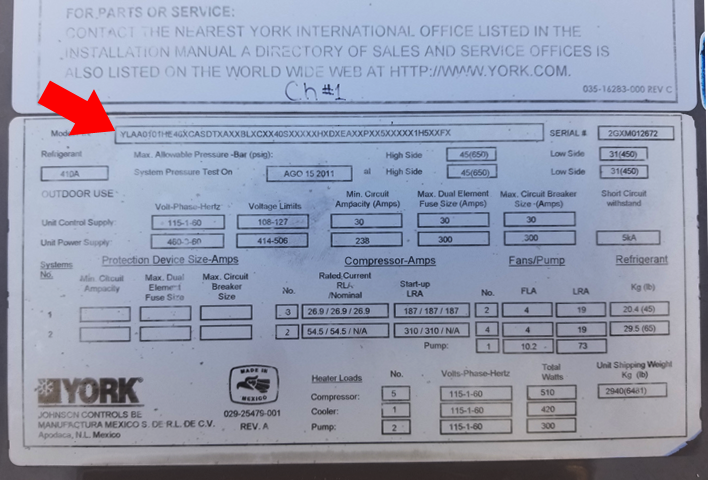

The most common YLAA units we encounter are the Style B models, which are built with microchannel condenser coils in both standard and high-efficiency versions. To tell the difference between the two, just check the model number. For example, "S" in YLAA0700SE stands for standard, while "H" in YLAA0156HE indicates high efficiency. A "ZE" in the model number, like in YLAA0080ZE, means the unit originally came with copper tube coils.

So, what’s the solution? Change the channel

Converting the microchannel in the YORK® YLAA chiller to a copper tube condenser coil can significantly improve reliability and make future servicing much easier — all while maintaining OEM efficiency levels.

One key point to remember: when upgrading from microchannel to copper tubes, you must replace the entire circuit. If one coil in a multi-coil system is leaking, you need to replace all of them. Depending on the size, YLAA units can have anywhere from 4 to 12 coils.

A York YLAA unit before microchannel conversion.

The same York YLAA unit after converting to copper tubes with a Blygold® coating.

If you only want to replace one coil, we recommend reaching out to York directly for an MCHX coil. At Nationwide Coils, we don’t do partial replacements because it’s just a temporary fix. It doesn’t resolve the underlying issues that plague the YLAA series.

Although the YORK YLAA is one of the most commonly upgraded units, we can perform a microchannel conversion on any make or model — no exceptions.

The Nationwide Coils Blog is a commercial HVAC blog written by industry experts with nearly two decades of experience in the field. We provide valuable insights into commercial HVAC products and services, and we encourage you to reach out to us anytime.

The length and width of the deep well plate comply with the SBS international standards. The depth of wells is increased based on the appearance and size of normal plates (mainly 96-well and 384-well plates) to enlarge the volume of each well. In addition, the manufacturing material(currently mostly used is polypropylene (PP)) is changed and the surface treatment process has been improved for this series of deep well plates to adapt to its specific use range. The deep well plates of NEST have a variety of specifications, conforming with the needs of fully automatic workstations and experiments.

Features:

Deep Well Plates,U-Bottom Plastic Comb,Transparent Plastic Comb Sterile,8-Well Plastic Comb

Wuxi NEST Biotechnology Co.,Ltd , https://www.nest-biotech.com