“Get Your Fix†Part 2 of 10: YORK® YLAA

Continuing our countdown of the top 10 commercial OEM condenser coils that have faced issues over the past decade, we now take a closer look at the York® YLAA series — one of the most commonly reported problematic units in the industry.

As we continue our coil issue countdown, we're diving into the YORK® YLAA chiller — a model that has consistently struggled with operational problems and poor durability in its MCHX condenser coils. It's not uncommon for us to receive calls weekly from contractors and end users about leaks, corrosion, and other issues with the original microchannel coils on these units.

Many customers express frustration with the reliability of this OEM unit, which has led to a negative impact on York’s reputation. While York did offer both microchannel and copper tube coil options, the latter is rarely seen in the field. Most YLAA units are equipped with microchannel coils, making them more prone to failure over time.

The usual suspects

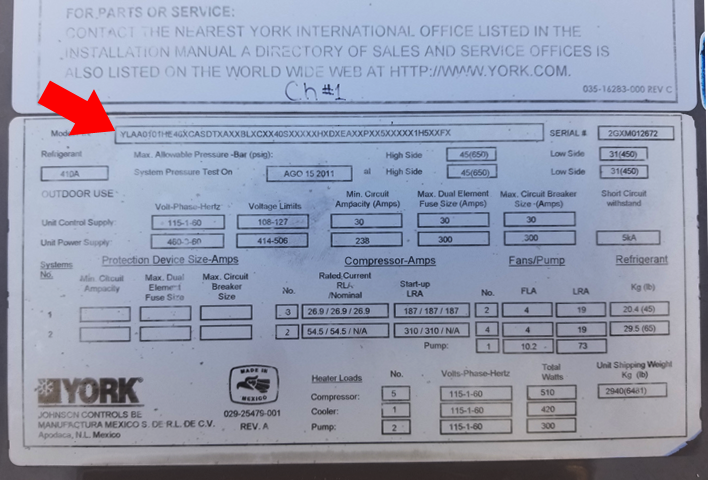

The most common YLAA models we encounter are the Style B units, which are typically built with microchannel condenser coils in both standard and high-efficiency versions. To identify whether you're dealing with a standard or high-efficiency unit, just check the model number. For example, "S" in YLAA0700SE stands for standard, while "H" in YLAA0156HE indicates high efficiency. If you see a "ZE" in the model, like YLAA0080ZE, it means the unit originally came with copper tube coils.

So, what’s the solution? The answer is simple: change the channel.

Converting the microchannel in the YORK® YLAA chiller to a copper tube condenser coil can significantly improve reliability and make maintenance much easier, all while maintaining OEM efficiency levels.

One important thing to note: when upgrading from microchannel to copper tubes, you must replace the entire circuit. This means if one coil is leaking and it’s part of a multi-coil system (which they often are), you’ll need to replace all of them. Depending on the size, YLAA units can have anywhere from 4 to 12 coils.

A York YLAA unit before microchannel conversion.

The same York YLAA unit after converting the microchannel to copper tubes and applying a Blygold® coating.

If you're only looking to replace one coil, we recommend reaching out directly to York and purchasing an MCHX coil from them. At Nationwide Coils, we don’t perform partial replacements because it’s just a temporary fix that won’t resolve the underlying issues with the YLAA unit.

Although the YORK YLAA is one of the most frequently upgraded units, we can perform a microchannel conversion on any make or model. Whether you're dealing with an older unit or a newer system, we’ve got the expertise to help you upgrade to a more reliable and long-lasting solution.

The Nationwide Coils Blog is a commercial HVAC blog written by industry experts with nearly two decades of experience. We provide valuable insights into commercial HVAC products and services and encourage you to reach out to us anytime.

Wuxi NEST Biotechnology Co.,Ltd , https://www.nest-biotech.com